Organic matter - separated from municipal solid waste, or obtained directly from the carrier (catering establishments, schools, etc.), can be recycled in two ways: either biodegradation to obtain compost (biofertilizer) or anaerobic treatment with biogas and organo-mineral fertilizers.

Biofertilizer (composting)

Composting of organic waste is an accepted practice in the countries of the European Union. Technology is standardized. If there is a need for compost or if biogas production is unprofitable, the volume of its extraction does not allow to launch the energy facility, then it is advisable to use the technology of industrial or open biodegradation of organic waste (composting).

The system of organic waste biodegradation to produce compost involves:

- a system of conveyors,

- receiving bins,

- shredding equipment to crushing the organic matter,

- biodrums (or biothermal chambers, pits, sites or piles),

- crushing equipment to crush compost with a magnetic separator,

- grab crane.

At the first stage, organic matter (food waste, phytogeneous waste etc.) received after MSW sorting at a drum separator is transported by a belt conveyor to a storage hopper. The volume of a storage hopper is balanced with the day process capacity in the way that the organic matter should stay in it not more than 8 hours if the composting is carried out in piles, biothermal chambers, pits, or not more than 24 hours if the industrial method of composting is carried out.

After a storage hopper, the organic matter is transported for composting.

The organic matter composting workshop should include:

- a preliminary crushing room;

- a aeration room;

- a composting room;

- a room for finished compost crushing;

- a storage room for finished compost.

Trommels or crushers are used to crush the organic matter incoming for composting. During final crushing, hammer mills can also be used.

In the comppost process room (depending on the technology) should be placed:

- piles with natural aeration;

- piles with forced aeration;

- biothermal chambers;

- pits;

- facilities for industrial composting.

Biothermic chambers and out of chamber composting with forced aeration are allowed to be used in small towns and villages with a population of up to 50 thousand inhabitants, field composting - in cities with a population of 50-500 thousand inhabitants. In settlements with a population of more than 500 thousand inhabitants, it is allowed to use industrial composting.

The capital machinery of the main process building are horizontal rotating drums (biodrums). Processing is carried out in a two- or three-day cycle.

The size of the room for compost maturation, after the cycle of processing in biodrums, is determined considering the volume of organic matter and geometrical parameters of piles.

The room to store finished compost is located along the perimeter of composting sites. Its size is determined on 6 months compost production considering the geometrical parameters of piles.

Prepared compost is a finished product for marketing.

Biogas

The system of anaerobic digestion (AD/fermentation) of organic MSW substance consists of:

- systems of conveyors,

- receiving bins,

- shredding equipment,

- percolators,

- pumps,

- methane tanks,

- gasholders,

- heat exchangers,

- equipment for biogas cleaning.

MSW incoming to the plant undergoes dosimetric monitoring in accordance with the requirements of the Basic sanitary rules of radiation safety of Ukraine.

Biogas production is performed by anaerobic treatment (AD) of organic substance (food waste, vegetable waste etc.) separated from MSW.

Organic substance suitable for anaerobic digestion must meet the following requirements:

- be fresh;

- be hydraulically-transportable,

- do not contain inclusions of more than 30 mm in size and solid mineral particles with a density of more than 1100 t/m3.

Optimum parameters of a mass for anaerobic digestion: humidity - from 90% to 92%; ash content - from 15% to 16%; pH - from 6.9 to 8.0; the content of fatty acids - from 600 mg / l to 1500 mg / l; alkalinity - from 1500 mg CaCO3 / l to 3000 mg CaCO3 / l; C: N - from 10 to 16.

In order to ensure an optimal ratio of C: N and bigger amount of biogas production it is allowed to add other organic waste to the mass, which is about to be fermented: raw sludge of municipal sewage waters, humus. The fermenting mass should not contain substances that suppress the activity of methane-forming organisms in a concentration higher than the permissible one. These substances are:

- various forms of nitrogen;

- most of heavy, alkaline, alkaline-earth metals;

- sulfides;

- oxygen;

- antibiotics;

- disinfectants and other substances.

Biogas yield from food waste

|

Substance |

Dry matter % |

Organic dry matter % |

Biogas yield м3/т |

Methane CH4 % |

|

Soya peelings |

90.0 |

95.1 |

516.7 |

52.7 |

|

Potato spent wash, fresh |

6.0 |

86.7 |

35.0 |

56.3 |

|

Oat flakes |

91.0 |

98.1 |

619.7 |

53.5 |

|

Brewery mash, fresh |

24.0 |

95.5 |

122.2 |

59.3 |

|

Siftings |

89.0 |

86.5 |

262.4 |

50.7 |

|

Silo brewery mash |

26.0 |

95.2 |

136.5 |

59.1 |

|

Apple marrow |

22.0 |

97.6 |

111.6 |

51.7 |

|

Soya flour |

87.0 |

93.3 |

551.6 |

61.2 |

|

Wheat stillages, liquid |

6.0 |

94.0 |

36.1 |

58.9 |

|

Corn gluten |

90.5 |

97.9 |

597.1 |

66.0 |

|

Lactose |

100.0 |

99.7 |

756.0 |

50.0 |

|

Cow’s whole milk |

13.5 |

94.7 |

114.9 |

62.8 |

|

Beer yeast |

10.0 |

91.8 |

60.7 |

62.1 |

|

Beer yeast, dry |

90.0 |

91.9 |

505.8 |

61.0 |

|

Old bread |

65.0 |

97.2 |

482.0 |

52.8 |

|

Bakery waste |

87.7 |

97.1 |

650.6 |

52.8 |

|

Cheese diary waste |

79.3 |

94.0 |

673.8 |

67.5 |

|

Low-in-fat food waste |

14.4 |

81.5 |

75.4 |

59.8 |

|

High-in-fat food waste |

18.0 |

92.3 |

126.5 |

62.0 |

|

Butter-milk, fresh |

8.0 |

92.3 |

54.4 |

59.2 |

|

Casein |

88.0 |

93.1 |

567.4 |

69.1 |

|

Dried skim milk |

94.1 |

91.7 |

628.7 |

57.7 |

|

Rape meal |

88.6 |

92.1 |

496.1 |

59.8 |

|

Sunflower meal |

89.4 |

91.9 |

488.2 |

61.3 |

|

Different food waste |

40.0 |

50.0 |

120.0 |

60.0 |

|

Fat |

95.0 |

92.0 |

874.0 |

68.0 |

|

Glycerin |

100.0 |

99.5 |

845.7 |

50.0 |

|

Flax oil |

99.9 |

99.9 |

1222.6 |

68.0 |

|

Rape oil |

99.9 |

99.9 |

1197.6 |

68.0 |

|

Soya oil |

99.9 |

99.9 |

1222.6 |

68.0 |

|

Sunflower oil |

99.9 |

99.9 |

1222.6 |

68.0 |

Biogas characteristics

|

Characteristics |

Biogas components |

Biogas mixture (CH4-60%, CO2-40%) |

||||

|

CH4 |

CO2 |

H2 |

H2S |

N2 |

||

|

Volume fraction, % |

55-70 |

20-44 |

1 |

1 |

<3 |

100 |

|

Volumetric specific heat, МJ / м3 |

35,8 |

- |

10,8 |

22,8 |

- |

21,5 |

|

Flammability range (in air), % |

5-15 |

- |

4-30 |

4-45 |

- |

5-12 |

|

Flammability temperature, С |

+650 - +750 |

- |

+585 |

- |

- |

+650 - +750 |

|

Standard density, g / l |

0,72 |

1,98 |

0,9 |

1,54 |

- |

1,2 |

Fermentation is carried out in bioreactors-methane tanks, which are hermetic, with heat-waterproofing, have devices for organic matter loading and unloading of fermented organic matter and biogas outlet. Loading-unloading processes are performed automatically and continuously. To intensify methanogenesis, bioreactors must be equipped with mechanisms for forced mixing, crushing and heating.

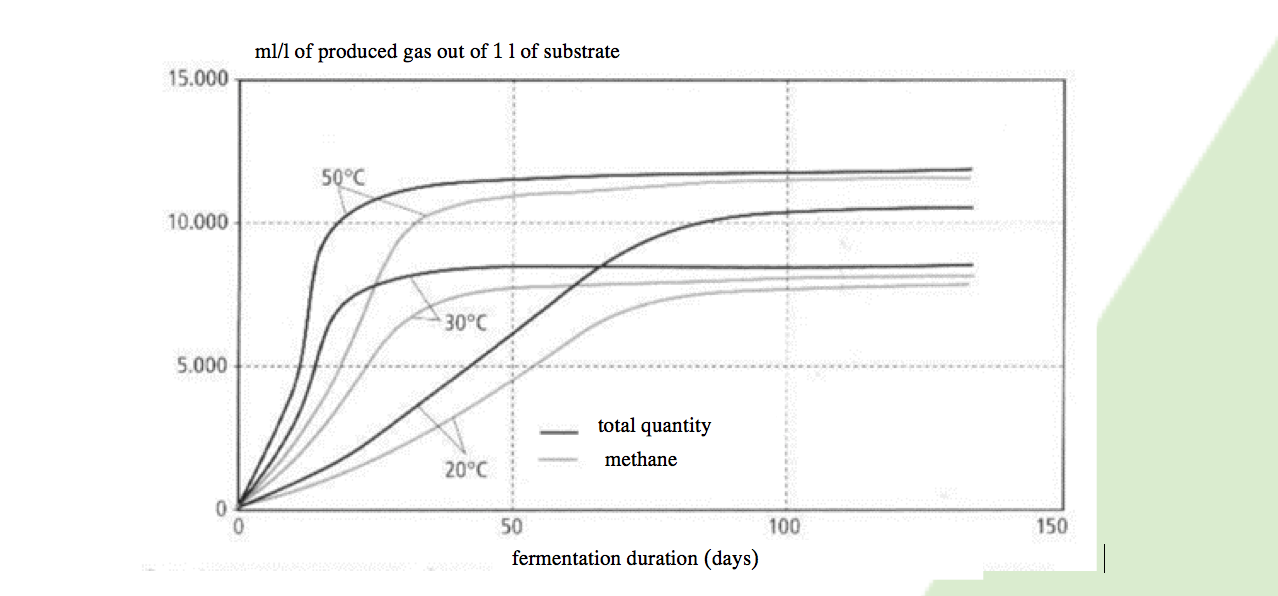

It is advisable to perform fermentation with heating and maintaining the temperatures: + 33°С ± 2°С (mesophilic mode), + 53 ° С ± 2 ° С (thermophilic mode). Duration of organic matter fermentation in a bioreactor depends on:

- physical and chemical properties of organic matter;

- temperature regime;

- given degree of organic matter decomposition.

Duration of the process: for mesophilic mode from 10 days to 30 days, for thermophilic mode - from 7 days to 15 days. The capacity of the methane tanks depends on the actual humidity of the organic matter and the daily loading dose, which is determined on the basis of experimental data and subsequent design calculations. Humidity of fermenting matter, which is being unloaded from the methane tank, is determined on loaded components ratio in solids.

Anaerobic digestion involves the following processes:

- Hydrolysis;

- Oxidation;

- Formation of acetic acid;

- Formation of methane;

The processes of anaerobic digestion can be single-stage or multi-stage processes. During one-stage digestion all four anaerobic stages are carried out in one reactor, that is, they are not separated in time or space. Multi-stage digestion processes (up to 4) allow increasing biogas output but having higher investment costs due to additional equipment and reactors.

Anaerobic treatment workshop includes the following buildings:

а) Buildings to prepare organic matter for anaerobic digestion, which allocate the following equipment:

- organic matter crushing equipment (crusher);

- equipment to dilute crushed organic matter tu the humidity of 90-92% (pumps, reservoirs);

- equipment to remove solids bigger than 30 mm in size (percolators);

- equipment for continuous transportation of prepared organic matter to heat exchangers to warm it up and load to reactors (reservoirs of methane tanks).

b) Anaerobic digestion building, which allocate the following:

- reactors with mixing equipment;

- pump station for organic matter pumping and for additional recirculatory mixing of organic matter;

- gas gathering station to get the gas from methane tanks and remove condensated water from it;

- gallery with elevator tower;

- gasholders to accumulate biogas;

- controlled flare unit, where the gas surplus is combusted in the case of emergency;

- refermented matter storage reservoir;

- centrifuges to separate solids and liquid;

- pasteurizer for compost;

- recirculating pumps and, if necessary, waste waters treatment plant for the surplus waters.

c) Buildings for methane tanks' biogas energy recovery to obtain electrical and thermal energy, which include:

- biogas preparation equipment to use biogas as fuel in boilers and dynamotors;

- heating plant (heat-exchanging equipment). Heat-exchanging equipment is used to heat organic matter, which is loaded into methane tanks, by a heat transfer agent – circulating reused water of waste heat recovery system with turbogenerator or cogeneration energy unit; the pump station of circulating reused water supply of the heat recovery system from a boiler or cogeneration unit and heat-exchanging equipment to heat the organic matter, which is loaded into methane tanks.

Fermented organic suspension goes through a centrifuge. Dehydrated solid fraction is characterized by high homogeneity and is a high-quality feedstock for compost production. If there is a need pasteurization is possible to be carried out. Afterwards, compost is stored in a reservoir for refermented matter.

Obtained biogas is combusted in boilers or dynamotors to receive thermal and/or electrical energy.