DEFINITION AND MAIN PURPOSE

Bioremediation - a complex of methods to purify water, soil and atmosphere using the metabolic potential of biological objects - plants, fungi, insects, worms and other organisms.

SHORT DESCRIPTION OF THE TECHNOLOGY

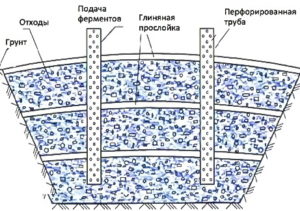

Volume bioremediation is a method of existing waste landfills utilization through a three-stage treatment, which on the first stage provides installation and connection of vertical perforated pipes to feed biologicals for disinfection and destruction of waste organics without excavation; on the second stage metal, glass, stones, and other non-organic materials are separated and transported for recycling; on the third stage the landfill is compressed and covered with a soil layer.Volume bioremediation can also be used for utilization of petroleum sedimentation basins, cleaning of polluted soils under gasoline stations, restoration of landscapes under different climatic conditions with cold climate including. Aqueous solutions of biologicals include solutions of enzymes, glucose, hydrogen peroxide, penetrators, dispersants, microbiological cultures etc.

The algorithm of works on the MSW landfill is as follows. Pipes are being prepared (their number and size depend on the size of the treated area), pipes are perforated throughout the length of the pipe. A solution is prepared for the sealing of pipes, bottom seal and plug with openings and pipes for air supply. Wells are drilled in a staggered manner at a predetermined distance (the distance between the wells depends on the results of preliminary laboratory tests). Pipes are inserted into each well. To prevent sharp leakage of water downwards and to perform evenly distribution of water through the openings - into the bottom of the pipes valves are installed. An enzyme preparation of the necessary concentration is being prepared. The solution is diluted with water and evenly poured into the wells, after which the pipes are covered with caps. The output of the pipe from the process map is sealed. Then the pipes are connected to each other and are connected to the compressor. Air is pumped through the process map during 25-30 minutes, then caps are removed till the next time. At the same time, the MSW surface treatment (all around the wells) by the biologicals solution is performed.

This method is tested, permitted and regulated by the acceleration of natural processes of biodegradation throughout the object of pollution, which ensures the guaranteed restoration of soil functions during one vegetation season, namely:

- In 15-20 days, an unpleasant, specific odor disappears completely

- In 40 days, insects, rodents, and animals leave

- In 60-90 days the volume of the landfill decreases by 30-50%

- In 120 emissions of CO2 in the atmosphere stop

- Sorting can be started

Advantages of this method:

- improvement of the ecological situation, reduction of the sanitary zone of the landfill

- low capital expenditures on technology implementation, compensation for emission reductions (in terms of СО2), compensation for the disposal of garbage, the possibility of electric and heat generation, switching to the green tariff

- high efficiency, landfill life extension

- vacation of the land

- adjustability at all stages

- short implementation period

- availability of permits for volumetric bioremediation at landfills

This technology was patented and has a successful result of application not only in Ukraine but also outside its borders, namely Poland, South Korea, CIS countries.

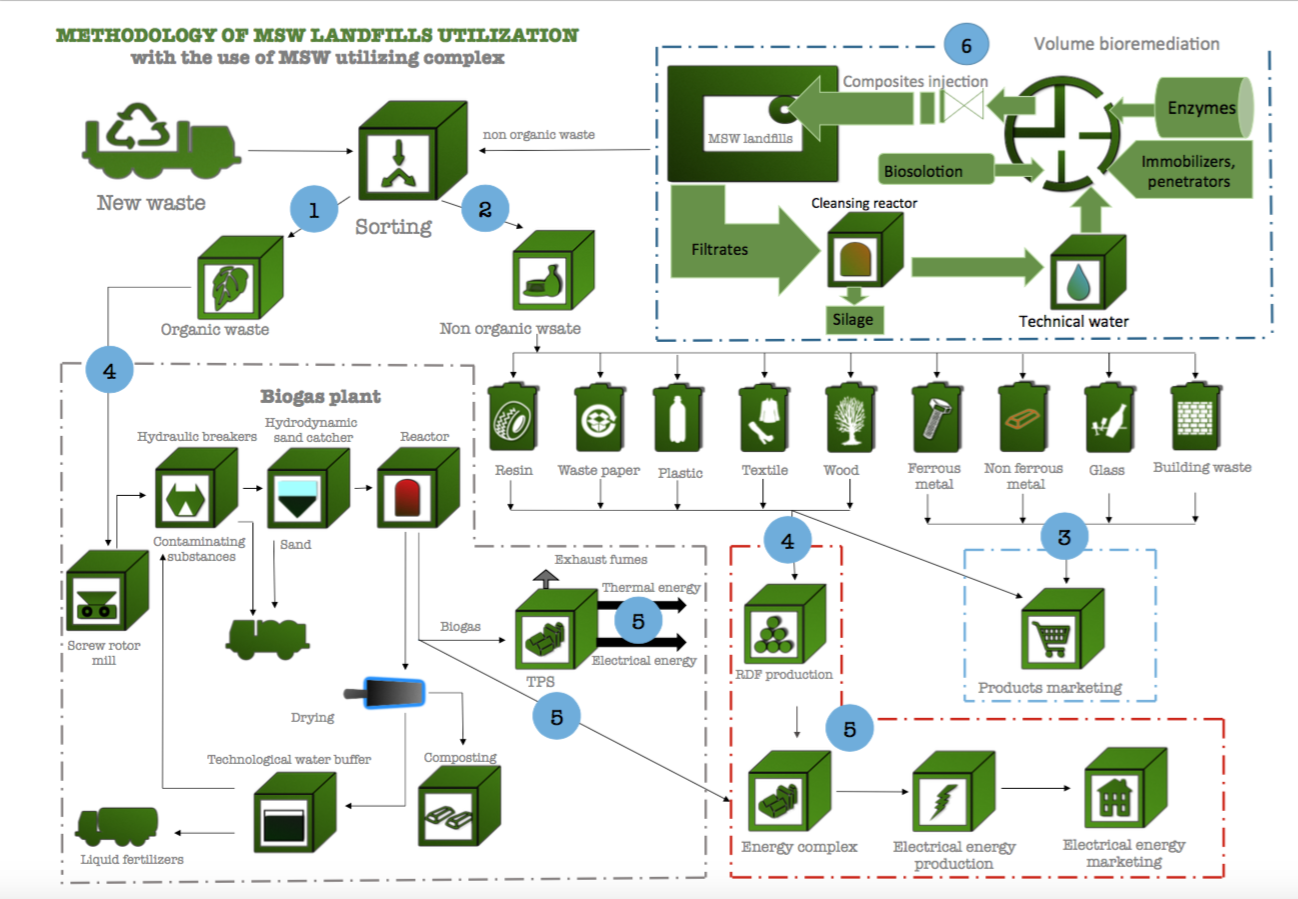

THE SCHEME OF VOLUME BIOREMEDIATION IMPLEMENTATION

as a part of the developed methodology

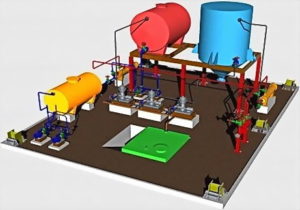

A complex consisting of containers, cleaning reactor, filtration systems and pumps is created at the MSW landfill

The filtrate that passed a purification system is collected in one of the containers. After that, it is passed for filtration and then the product falls into the collecting-draining vessel of industrial water

In parallel with this, on the basis of enzyme, protein compounds and microorganisms, biologics are prepared and mixed with industrial water and pumped into the injection wells, or sprayed around the MSW landfills

Volume bioremediation is the technology of full MSW landfill body utilization

This technology was tested and had a successful result of application not only in Ukraine but also outside its borders, namely Poland, South Korea, CIS countries.

Volume bioremediation – SOME PERFORMED PROJECTS

| ANALYSIS PARAMETERS OF OUTPUT GASES

Ukraine, MSW landfill 052810 Kramatorsk town |

||||

| Parameters | 03/Oct/2012 | 15/Oct/2012 | ||

| 1-st well | 2-nd well | 1-st well | 2-nd well | |

| H2S | 4,0 мг/м3 | >100,0 мг/м3 | 2,4 мг/м3 | 63,0 мг/м3 |

| CO | 64,2 мг/м3 | 235,0 мг/м3 | 30,4 мг/м3 | 25,8 мг/м3 |

| NH3 | 0,0 мг/м3 | 160,0 мг/м3 | 0,0 мг/м3 | 25,0 мг/м3 |

| O2 | 15,8 % | 0,0 % | 18,0 % | 16,1 % |

| Parameters | 25/Oct/2012 | 05/Nov/2012 | ||

| 1-st well | 2-nd well | 1-st well | 2-nd well | |

| H2S | 0,0 мг/м3 | 3,2 мг/м3 | 0,0 мг/м3 | 0,0 мг/м3 |

| CO | 14,2 мг/м3 | 11,2 мг/м3 | 9,2 мг/м3 | 6,7 мг/м3 |

| NH3 | 0,0 мг/м3 | 0,0 мг/м3 | 0,0 мг/м3 | 0,0 мг/м3 |

| O2 | 18,1 % | 16,3 % | 18,8 % | 17,1 % |

ANALYSIS PARAMETERS OF OUTPUT GASES

Ukraine, MSW landfil Novoiavorivsk, well № 3

| 05 серпня 2015 | ||

| Parameters | Readings | Class of danger |

| CnHm | 110,9 %НКПР | П2 |

| NH3 | 23 мг/м3 | П1 |

| H2S | 10,2 мг/м3 | П1 |

| CL2 | 3,79 мг/м3 | П1 |

| O2 | 17,9 % | |

| 27 вересня 2015 | ||

| Parameters | Readings | Class of danger |

| CnHm | 1,4 %НКПР | |

| NH3 | 0,1 мг/м3 | |

| H2S | 0 мг/м3 | |

| CL2 | 0 мг/м3 | |

| O2 | 20,2 % | |

Volume bioremediation of MSW landfill in Gdansk city, Poland

This stadium is built on the land where previously an MSW landfill was situated

Stadium may hold 44 000 people