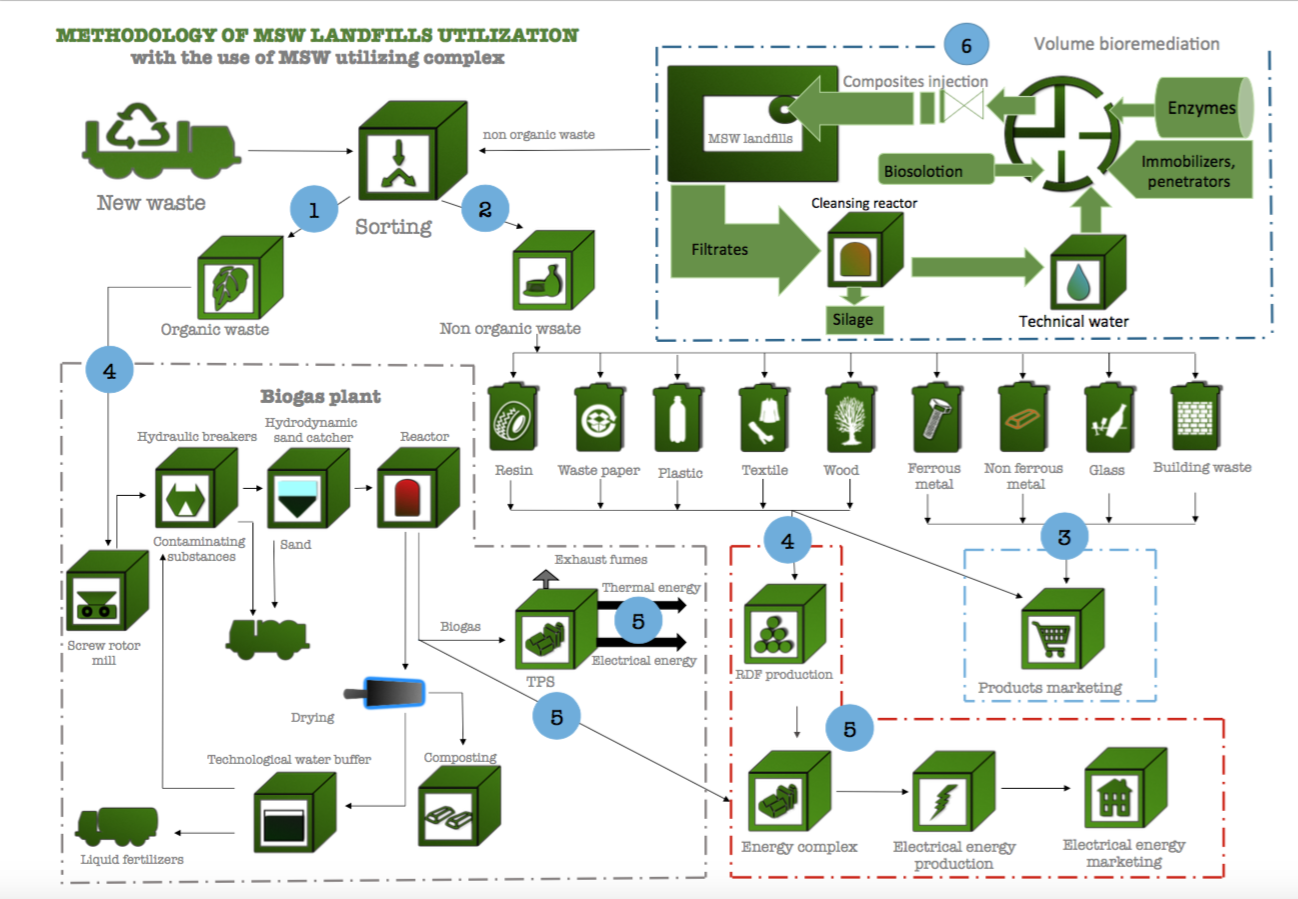

We would like to bring to your attention a method for the complete utilization of municipal solid waste landfills.

The proposed methodology is based on studies of waste management technologies existing in the market. On the basis of the analysis performed the technological lines that allow recycling and utilization of up to 85% of municipal solid waste (MSW) have been identified. In some cases (depending on the morphology and the need for the removal of solid non-combustible waste), the figure can reach up to 96%. The principle of "maximum waste utilization rate at a minimum cost of initial investment" was applied to choose the technological processes and lines. The technological lines, plants, aggregates and technologies offered in this methodology are generally accepted and applied in many countries around the world.

This methodology provides for the modularity of the entire system. The "modular principle" is at the heart of the methodology and allows its expansion, reorientation, improvement etc. In addition, such an approach allows the formation of such a technological process, which takes into account characteristics of MSW morphology in the region, market of secondary raw materials, energy needs and energy distribution modes.

This methodology provides for the modularity of the entire system. The "modular principle" is at the heart of the methodology and allows its expansion, reorientation, improvement etc. In addition, such an approach allows the formation of such a technological process, which takes into account characteristics of MSW morphology in the region, market of secondary raw materials, energy needs and energy distribution modes.

In connection with the above matter, we have developed the concept of an existing MSW landfill modernization into an MSW recycling complex, which makes it possible to use profit earned to recultivate the body of an existing old MSW landfill through volume bioremediation application.

METHODOLOGY

SEMI-AUTOMATIC SORTING

- organic matter separation

- non-organic matter sorting

At this stage, an automatic separation of the organic matter of incoming waste takes place. At the next stage, biogas is produced from separated organic matter. Also, optionally, a variant of fertilizers production for own needs or for sale is offered.

The non-organic matter of waste is sorted manually into the following components for recycling: plastics, food-grade aluminum, glass, waste paper etc. Received secondary raw material is sent to the press-packing unit for further processing or sale.

BIOTECHNOLOGICAL PROCESSING

- biofuel production

- organic-humus fertilizers production

The main macro-components of gas formed during the decomposition of organic garbage in landfills are methane (CH4) and carbon dioxide (CO2). Each ton of organic garbage can give 300 to 800 m3 of biofuel. Biofuel is a mixture of methane, carbon dioxide, nitrogen and water vapor. Such biofuel is used for obtaining heat and electricity from it and for its subsequent sale on the terms of the Green Tariff and use for own needs.

Organic-humus fertilizers that are produced as a by-product of methane digestion of a biogas plant do not contain pathogenic organisms and weed seeds and can be used both for own needs and for sale.

SECONDARY RAW MATERIAL PRODUCTION

- non-organic waste sorting

- press-packing

After manual sorting, residual non-organic waste is passed through magnetic and non-magnetic detectors, vibration sieve, to separate ferrous and non-ferrous metals, solid minerals. All types of received secondary raw materials are gradually reduced to a fraction of 10-50 mm (depending on the requirements of the Customer), washed, pressed and packed in bales for the purpose of further re-sale, sale or use for own needs.

ENERGY PRODUCTION

- Thermal energy

- Electrical energy

- Thermal and electrical energy

The energy generating complex is the main production unit of this methodology. Its presence in the configuration of the integrated waste recycling and utilization plant allows to solve the following tasks:

- Performs the function of a co-generation unit in the production of biogas;

- Generates thermal energy for the production of compost;

- Carries out the utilization of all combustible components of solid waste (except hazardous waste);

RDF FUEL PRODUCTION

- primary RDF fuel

- RDF fuel

Primary RDF fuel - residual waste after all stages of sorting, which is not subject to recycling. Usually - up to 50% of all garbage. RDF fuel is obtained in the way of shredding, separating, removing of contaminating elements and further dehydrating of the primary RDF fuel. The resulting RDF fuel is used for the production of heat and electricity and their subsequent sale under the terms of Green Tariff and use for own needs.

RDF-fuel TU U 38.1-39365144-001: 2018, Statement of the State Consumer Service, №602-123-20-2 / 44642 dated 29.10.2018 (These specifications are the design and property of NBTR LLC)

SRF-fuel TU U 38.1-39365144-002: 2019, Statement of the State Consumer Service, No. 602-123-20-2 / 645 dated 16.01.2019 (These specifications are the design and property of NBTR LLC)

VOLUME BIOREMEDIATION

- utilization of organic matter of MSW landfill without excavation

- complete utilization of the MSW landfill body

Volume bioremediation - a method of MSW landfills utilization through a three-stage process, which at the first stage includes installation of perforated pipes connected into a system of vertical perforated sections of pipes, where through biologics are feeded for disinfection and destroy of waste organic matter without excavation; at the second stage, metal, glass, stones, the residual of building materials are sorted and transported for further processing; at the third stage, the landfill is compressed and covered with a layer of soil. Enzymes that are fed under pulsating pressure are used as biologicals and perforated vertical pipe areas are chessed among the body of the landfill.

Technology includes:

- Sorting

- Organic matter utilization in the way of:

- fertilizers production,

- biogas production with a further production of fertilizers from biogas by-products;

- Complete selection of secondary raw materials for sale;

- Production of high-calorie RDF fuel;

- Production of heat and/or electric energy;

- Final stage - conducting volumetric bioremediation in the body of the MSW landfill, further sorting of garbage and complete utilization of the MSW landfill body.

- Use or sale of lands after their recultivation and reduction of the sanitary zone to 150 meters.

While developing this methodology we were guided by the following regulatory documents.

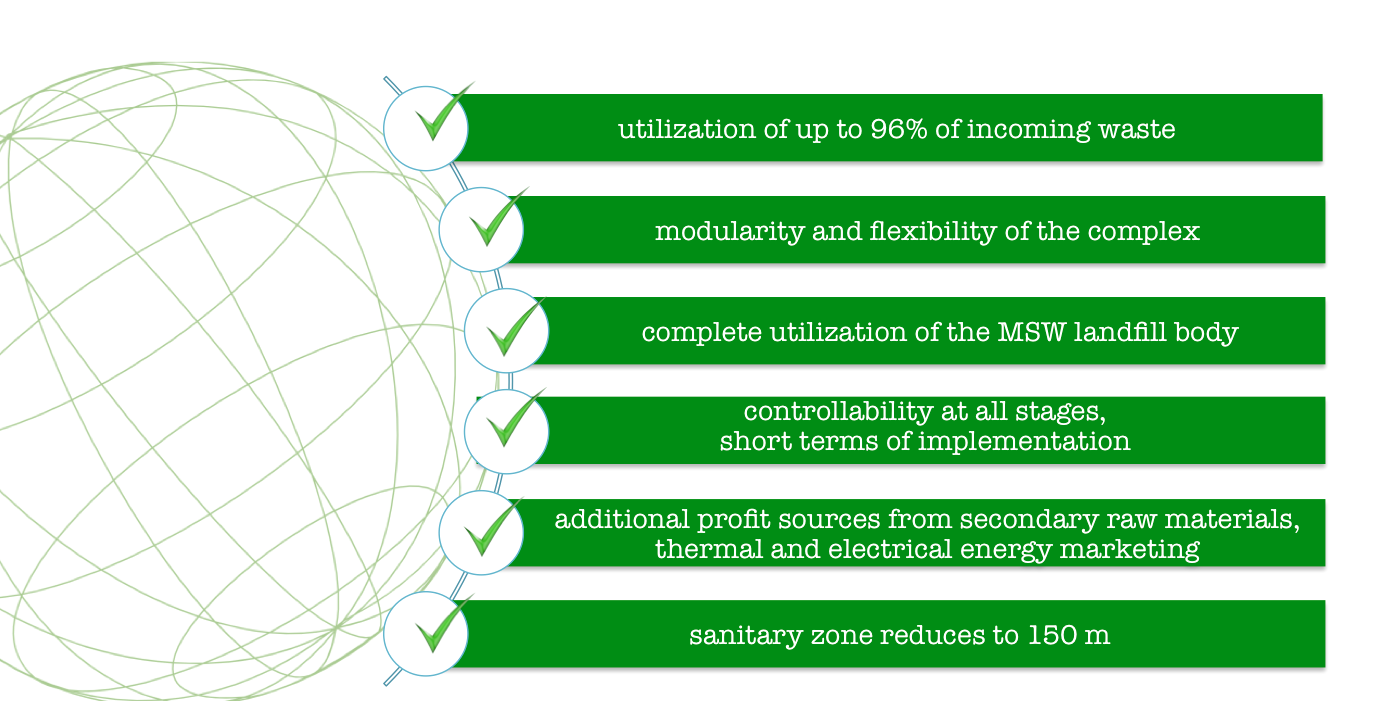

ADVANTAGES OF THE METHODOLOGY

___________________________________________________

___________________________________________________

___________________________________________________________________________________

Address: Ukrayina, m.Kyyiv, vul.Yaltyn'ska, bud. 5B

Tel.: +38 (044) 389-81-81

E-mail: info@nbtr.com.ua

OUR OFFICE: